<sources>

<sources>- <porous>

For thermal simulations, the porous media source type is extended to describe the

thermal characteristics of a heat exchanger. Each

<porous_instance> can be extended with the following parameters:

- <thermal_type> (none, constant_fluid_temperature, constant_coolant_temperature, constant_heat) Default: none;

- This parameter specifies the type of heat exchanger.

- none

- No heat exchanger is specified. Porous media remains as a simple porous block.

- constant_fluid_temperature

- For this type of heat exchanger a constant fluid temperature is enforced across the whole volume of the porous medium. This temperature can be set as an additional parameter via <temperature>.

- constant_coolant_temperature

- For this heat exchanger type the inlet coolant temperature remains constant. The coolant exit temperature is calculated by ultraFluidX which, in turn, requires thermal performance data, coolant flow rate, specific heat and a reference part name. Air inlet quantities are taken from a reference surface upstream of the heat exchanger. This reference surface must be provided by you in the form of an .stl file. This type of heat exchanger is defined by the following parameters.

Additional parameters for

constant_fluid_temperature

- <temperature> default = 293.15

- Specifies the value of temperature in K for the fluid.

Additional parameters for

constant_coolant_temperature

- <temperature> default = 293.15

- Specifies the value of temperature in K for the coolant.

- <coolant_mass_flow_rate> default = 0

- Specifies the mass flow rate of the coolant in [kg/s].

- <coolant_specific_heat_capacity> default = 0

- Specifies the heat capacity of the coolant [J/kg/K].

- <heat_coefficients> default = 0

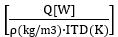

- Specifies the thermal performance of the heat exchanger in the form of

coefficients of 2nd-order polynomial curve fit of

against velocity (m/s). ITD

refers to initial temperature difference (inlet coolant temperature – inlet

air temperature) and 𝜌 is the air density. Three coefficients of the

polynomial curve fit are specified via the child parameters:

against velocity (m/s). ITD

refers to initial temperature difference (inlet coolant temperature – inlet

air temperature) and 𝜌 is the air density. Three coefficients of the

polynomial curve fit are specified via the child parameters: - <reference_part>

- Part name of a reference surface in the .stl input. A reference surface, which is placed upstream of the heat exchanger, is used to measure the averaged air inlet mass flow rate of the heat exchanger. The reference part is treated as a monitoring surface in ultraFluidX. Relevant information of the reference part and its corresponding heat exchanger such as coolant inlet temperature, coolant exit temperature, rejected heat are printed in the uFX_monitoring_surface_<name>/uFX_monitoring_surface.txt file of the reference part.

- <reference_part_update_frequency> default = 1

- The frequency at which the averaged quantities of the reference part are updated.

- <reference_part_summary_output>

- Specifies the summary output of the reference part that is written. The start and the frequency of the summary output of the reference part is specified by the child parameter <output_start_iteration> and <output_frequency>, respectively.

- <reference_part_visual_output>

- Specifies the visual output of the variables on the reference part via the child parameters:

Additional parameters for

constant_heat

For the type <thermal_type> constant_heat, constant heat [in

W] is applied uniformly to the heat exchanger. This type of heat exchanger requires

the following additional parameters:

- <heat> default 0

- Specified heat applied to the heat exchanger in W.

For the <thermal_type> constant_heat, it is optional to output the coolant exit temperature.

In this case, the following parameters are required (cf. constant_coolant_temperature type):

<coolant_mass_flow_rate>

<coolant_specific_heat_capacity>

<heat_coefficients>

<reference_part>

The coolant exit temperature is then written in the uFX_monitoring_surface_<name>/uFX_monitoring_surface.txt file of the reference part.