/MAT/LAW36 (PLAS_TAB)

Block Format Keyword This law models an isotropic elasto-plastic material using user-defined functions for the work-hardening portion of the stress-strain curve (for example, stress versus plastic strain) for different strain rates.

For Solid and SPH elements, this material may account for the nonlinear dependence between pressure and density when corresponding Equation of State is prescribed.

Format

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| /MAT/LAW36/mat_ID/unit_ID or /MAT/PLAS_TAB/mat_ID/unit_ID | |||||||||

| mat_title | |||||||||

| E | |||||||||

| Nfunct | Fsmooth | Chard | Fcut | VP | |||||

| fct_IDp | Fscale | fct_IDE | Einf | CE | |||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| fct_ID1 | fct_ID2 | fct_ID3 | fct_ID4 | fct_ID5 |

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| Fscale1 | Fscale2 | Fscale3 | Fscale4 | Fscale5 | |||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

Definition

| Field | Contents | SI Unit Example |

|---|---|---|

| mat_ID | Material identifier. (Integer, maximum 10 digits) |

|

| unit_ID | Unit identifier. (Integer, maximum 10 digits) |

|

| mat_title | Material title. (Character, maximum 100 characters) |

|

| Initial density. (Real) |

||

| E | Young's modulus. (Real) |

|

| Poisson's ratio. (Real) |

||

| Failure plastic strain. 11 Default = 1020 (Real) |

||

| Tensile failure strain at which stress

starts to reduce. 2 Default = 1020 (Real) |

||

| Maximum tensile failure strain at which

the stress in element is set to zero. 2 Default = 2.0 x 1020 (Real) |

||

| Nfunct | Number of functions (

). (Integer) |

|

| Fsmooth | Smooth strain rate option flag.

(Integer) |

|

| Chard | Hardening coefficient.

(Real) |

|

| Fcut | Cutoff frequency for strain rate

filtering. Only available for shell and solid elements, Appendix: Filtering. 16 Default = 10000 Hz (Real) |

|

| VP | Strain rate choice flag. 17

(Integer) |

|

| Tensile strain for element deletion.

2 Default = 3.0 x 1020 (Real) |

||

| fct_IDp | Yield factor versus pressure function.

7 Default = 0 (Integer) |

|

| Fscale | Scale factor for yield factor in fct_IDp. Default = 1.0 (Real) |

|

| fct_IDE | Function identifier for the scale factor

of Young's modulus, when Young's modulus is function of the plastic strain. 16 Default = 0: in this case the evolution of Young's modulus depends on Einf and CE. (Integer) |

|

| Einf | Saturated Young's modulus for infinitive

plastic strain. (Real) |

|

| CE | Parameter for Young's modulus

evolution. (Real) |

|

| fct_ID1 | Yield stress function identifier 1

corresponding to strain rate

. (Integer) |

|

| fct_ID2 | Yield stress function identifier 2

corresponding to strain rate

. (Integer) |

|

| fct_ID3 | Yield stress function identifier 3

corresponding to strain rate

. (Integer) |

|

| fct_ID4 | Yield stress function identifier 4

corresponding to strain rate

. (Integer) |

|

| fct_ID5 | Yield stress function identifier 5

corresponding to strain rate

. (Integer) |

|

| Fscale1 | Scale factor for ordinate (stress) in

fct_ID1. Default = 1.0 (Real) |

|

| Fscale2 | Scale factor for ordinate (stress) in

fct_ID2. Default = 1.0 (Real) |

|

| Fscale3 | Scale factor for ordinate (stress) in

fct_ID3. Default = 1.0 (Real) |

|

| Fscale4 | Scale factor for ordinate (stress) in

fct_ID4. Default = 1.0 (Real) |

|

| Fscale5 | Scale factor for ordinate (stress) in

fct_ID5. Default = 1.0 (Real) |

|

| If VP

=0 total strain rate for fct_ID1. If VP =1 plastic strain rate for fct_ID1. (Real) |

||

| If VP

=0 total strain rate for fct_ID2. If VP =1 plastic strain rate for fct_ID2. (Real) |

||

| If VP

=0 total strain rate for fct_ID3. If VP =1 plastic strain rate for fct_ID3. (Real) |

||

| If VP

=0 total strain rate for fct_ID4. If VP =1 plastic strain rate for fct_ID4. (Real) |

||

| If VP

=0 total strain rate for fct_ID5. If VP =1 plastic strain rate for fct_ID5. (Real) |

Example (Steel)

#RADIOSS STARTER

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/UNIT/1

unit for mat

g mm ms

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#- 2. MATERIALS:

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

##HWCOLOR materials 1 43

/MAT/PLAS_TAB/1/1

MAT_TABULATED_STEEL_EXAMPLE

# Init. dens.

0.0078

# E Nu Eps_p_max Eps_t Eps_m

221000.0 0.3

# N_funct F_smooth C_hard F_cut Eps_f VP

5 1

# fct_IDp Fscale Fct_IDE EInf CE

# func_ID1 func_ID2 func_ID3 func_ID4 func_ID5

1 2 3 4 4

# Fscale_1 Fscale_2 Fscale_3 Fscale_4 Fscale_5

1.0 1.0 1.0 1.0 1.001

# Eps_dot_1 Eps_dot_2 Eps_dot_3 Eps_dot_4 Eps_dot_5

0.0 0.01 0.1 1.0 1000.0

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

##HWCOLOR curves 1 59

/FUNCT/1

#title

TrueYieldStressMPa_vs_TruePlasticStrain - QUASI_STATIC

# X Y

0.0 389.67

0.003269060686992 400.23

0.006930111818697 412.0

0.010444667419264 425.0

0.01364836646806 435.0

0.018589301580824 452.254

0.021874379924321 469.641

0.025339482510186 483.105

0.028791504254908 494.684

0.032231428223083 505.957

0.035658606063999 515.583

0.039073857673036 524.886

0.042476834476844 533.05

0.045868260757615 541.266

0.049247691998806 548.545

0.052615532789687 555.47

0.055971597355424 561.572

0.0593166151509 568.02

0.062650302953907 574.173

0.065972157272864 578.918

0.069283274188388 584.179

0.072583138868944 588.852

0.075872187258015 593.598

0.079150038252912 597.579

0.082417501766217 602.191

0.085673728163777 605.639

0.088919522946915 609.378

0.092154789311739 613.072

0.095379504511807 616.55

0.098593691533105 619.695

0.101797797028468 623.305

0.10499136344905 626.295

0.10817487992333 629.521

0.111348320564453 632.813

0.114511357347318 635.359

0.117664394244064 637.851

0.120807432277488 640.171

0.123940737206559 642.727

0.127064395848652 645.58

0.130178020896066 647.79

0.133282182305355 650.415

0.136376459004361 652.452

0.139461485892449 655.142

0.142536808253643 657.36

0.145602624330452 659.399

0.148658992471595 661.25

0.151706339300304 663.779

0.154744128728257 665.639

0.157772590056329 667.195

0.1607925194482 670.145

0.163802712305892 671.639

0.166804116095314 673.679

0.169796748990641 676.21

0.172779797696021 677.208

0.175754158491204 678.631

0.178719690345003 680.05

0.181676645262092 681.9

0.184624849171709 683.687

0.187564155022526 684.911

0.190494821916083 686.069

0.193600270631344 686.606

0.196220092476069 687.801

0.199417970430916 689.022

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

##HWCOLOR curves 2 59

/FUNCT/2

#title

TrueYieldStressMPa_vs_TruePlasticStrain - 10s-1

# X Y

0.0 409.1535

0.003269060686992 420.2415

0.006930111818697 432.6

0.010444667419264 446.25

0.01364836646806 456.75

0.018589301580824 474.8667

0.021874379924321 493.12305

0.025339482510186 507.26025

0.028791504254908 519.4182

0.032231428223083 531.25485

0.035658606063999 541.36215

0.039073857673036 551.1303

0.042476834476844 559.7025

0.045868260757615 568.3293

0.049247691998806 575.97225

0.052615532789687 583.2435

0.055971597355424 589.6506

0.0593166151509 596.421

0.062650302953907 602.88165

0.065972157272864 607.8639

0.069283274188388 613.38795

0.072583138868944 618.2946

0.075872187258015 623.2779

0.079150038252912 627.45795

0.082417501766217 632.30055

0.085673728163777 635.92095

0.088919522946915 639.8469

0.092154789311739 643.7256

0.095379504511807 647.3775

0.098593691533105 650.67975

0.101797797028468 654.47025

0.10499136344905 657.60975

0.10817487992333 660.99705

0.111348320564453 664.45365

0.114511357347318 667.12695

0.117664394244064 669.74355

0.120807432277488 672.17955

0.123940737206559 674.86335

0.127064395848652 677.859

0.130178020896066 680.1795

0.133282182305355 682.93575

0.136376459004361 685.0746

0.139461485892449 687.8991

0.142536808253643 690.228

0.145602624330452 692.36895

0.148658992471595 694.3125

0.151706339300304 696.96795

0.154744128728257 698.92095

0.157772590056329 700.55475

0.1607925194482 703.65225

0.163802712305892 705.22095

0.166804116095314 707.36295

0.169796748990641 710.0205

0.172779797696021 711.0684

0.175754158491204 712.56255

0.178719690345003 714.0525

0.181676645262092 715.995

0.184624849171709 717.87135

0.187564155022526 719.15655

0.190494821916083 720.37245

0.193600270631344 720.9363

0.196220092476069 722.19105

0.199417970430916 723.4731

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

##HWCOLOR curves 3 59

/FUNCT/3

#title

TrueYieldStressMPa_vs_TruePlasticStrain - 100s-1

# X Y

0.0 428.0

0.003269060686992 440.0

0.006930111818697 453.0

0.010444667419264 467.0

0.01364836646806 478.0

0.018589301580824 497.0

0.021874379924321 516.0

0.025339482510186 531.0

0.028791504254908 544.0

0.032231428223083 556.0

0.035658606063999 567.0

0.039073857673036 577.0

0.042476834476844 586.0

0.045868260757615 595.0

0.049247691998806 603.0

0.052615532789687 611.0

0.055971597355424 617.0

0.0593166151509 624.0

0.062650302953907 631.0

0.065972157272864 636.0

0.069283274188388 642.0

0.072583138868944 647.0

0.075872187258015 652.0

0.079150038252912 657.0

0.082417501766217 662.0

0.085673728163777 666.0

0.088919522946915 670.0

0.092154789311739 674.0

0.095379504511807 678.0

0.098593691533105 681.0

0.101797797028468 685.0

0.10499136344905 688.0

0.10817487992333 692.0

0.111348320564453 696.0

0.114511357347318 698.0

0.117664394244064 701.0

0.120807432277488 704.0

0.123940737206559 706.0

0.127064395848652 710.0

0.130178020896066 712.0

0.133282182305355 715.0

0.136376459004361 717.0

0.139461485892449 720.0

0.142536808253643 723.0

0.145602624330452 725.0

0.148658992471595 727.0

0.151706339300304 730.0

0.154744128728257 732.0

0.157772590056329 733.0

0.1607925194482 737.0

0.163802712305892 738.0

0.166804116095314 741.0

0.169796748990641 743.0

0.172779797696021 744.0

0.175754158491204 746.0

0.178719690345003 748.0

0.181676645262092 750.0

0.184624849171709 752.0

0.187564155022526 753.0

0.190494821916083 754.0

0.193600270631344 755.0

0.196220092476069 756.0

0.199417970430916 757.0

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

##HWCOLOR curves 4 59

/FUNCT/4

#title

TrueYieldStressMPa_vs_TruePlasticStrain - 1000s-1

# X Y

0.0 467.0

0.003269060686992 480.0

0.006930111818697 494.0

0.010444667419264 510.0

0.01364836646806 522.0

0.018589301580824 542.0

0.021874379924321 563.0

0.025339482510186 579.0

0.028791504254908 593.0

0.032231428223083 607.0

0.035658606063999 618.0

0.039073857673036 629.0

0.042476834476844 639.0

0.045868260757615 649.0

0.049247691998806 658.0

0.052615532789687 666.0

0.055971597355424 673.0

0.0593166151509 681.0

0.062650302953907 689.0

0.065972157272864 694.0

0.069283274188388 701.0

0.072583138868944 706.0

0.075872187258015 712.0

0.079150038252912 717.0

0.082417501766217 722.0

0.085673728163777 726.0

0.088919522946915 731.0

0.092154789311739 735.0

0.095379504511807 739.0

0.098593691533105 743.0

0.101797797028468 747.0

0.10499136344905 751.0

0.10817487992333 755.0

0.111348320564453 759.0

0.114511357347318 762.0

0.117664394244064 765.0

0.120807432277488 768.0

0.123940737206559 771.0

0.127064395848652 774.0

0.130178020896066 777.0

0.133282182305355 780.0

0.136376459004361 782.0

0.139461485892449 786.0

0.142536808253643 788.0

0.145602624330452 791.0

0.148658992471595 793.0

0.151706339300304 796.0

0.154744128728257 798.0

0.157772590056329 800.0

0.1607925194482 804.0

0.163802712305892 805.0

0.166804116095314 808.0

0.169796748990641 811.0

0.172779797696021 812.0

0.175754158491204 814.0

0.178719690345003 816.0

0.181676645262092 818.0

0.184624849171709 820.0

0.187564155022526 821.0

0.190494821916083 823.0

0.193600270631344 823.0

0.196220092476069 825.0

0.199417970430916 826.0

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#ENDDATA

/END

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|Example (Steel with EoS)

#RADIOSS STARTER

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/UNIT/1

unit for mat

g mm ms

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#- 2. MATERIALS:

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

##HWCOLOR materials 1 43

/MAT/PLAS_TAB/1/1

MAT_TABULATED_STEEL_EXAMPLE

# Init. dens.

0.0078

# E Nu Eps_p_max Eps_t Eps_m

221000.0 0.3

# N_funct F_smooth C_hard F_cut Eps_f VP

5 1

# fct_IDp Fscale Fct_IDE EInf CE

# func_ID1 func_ID2 func_ID3 func_ID4 func_ID5

1 2 3 4 4

# Fscale_1 Fscale_2 Fscale_3 Fscale_4 Fscale_5

1.0 1.0 1.0 1.0 1.001

# Eps_dot_1 Eps_dot_2 Eps_dot_3 Eps_dot_4 Eps_dot_5

0.0 0.01 0.1 1.0 1000.0

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/EOS/GRUNEISEN/1/1

EOS_STEEL_EXAMPLE

# C S1 S2 S3

457 1.490 0 0

# GAMMA0 ALPHA E0

2.00 .50 0

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

##HWCOLOR curves 1 59

/FUNCT/1

#title

TrueYieldStressMPa_vs_TruePlasticStrain - QUASI_STATIC

# X Y

0.0 389.67

0.003269060686992 400.23

0.006930111818697 412.0

0.010444667419264 425.0

0.01364836646806 435.0

0.018589301580824 452.254

0.021874379924321 469.641

0.025339482510186 483.105

0.028791504254908 494.684

0.032231428223083 505.957

0.035658606063999 515.583

0.039073857673036 524.886

0.042476834476844 533.05

0.045868260757615 541.266

0.049247691998806 548.545

0.052615532789687 555.47

0.055971597355424 561.572

0.0593166151509 568.02

0.062650302953907 574.173

0.065972157272864 578.918

0.069283274188388 584.179

0.072583138868944 588.852

0.075872187258015 593.598

0.079150038252912 597.579

0.082417501766217 602.191

0.085673728163777 605.639

0.088919522946915 609.378

0.092154789311739 613.072

0.095379504511807 616.55

0.098593691533105 619.695

0.101797797028468 623.305

0.10499136344905 626.295

0.10817487992333 629.521

0.111348320564453 632.813

0.114511357347318 635.359

0.117664394244064 637.851

0.120807432277488 640.171

0.123940737206559 642.727

0.127064395848652 645.58

0.130178020896066 647.79

0.133282182305355 650.415

0.136376459004361 652.452

0.139461485892449 655.142

0.142536808253643 657.36

0.145602624330452 659.399

0.148658992471595 661.25

0.151706339300304 663.779

0.154744128728257 665.639

0.157772590056329 667.195

0.1607925194482 670.145

0.163802712305892 671.639

0.166804116095314 673.679

0.169796748990641 676.21

0.172779797696021 677.208

0.175754158491204 678.631

0.178719690345003 680.05

0.181676645262092 681.9

0.184624849171709 683.687

0.187564155022526 684.911

0.190494821916083 686.069

0.193600270631344 686.606

0.196220092476069 687.801

0.199417970430916 689.022

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

##HWCOLOR curves 2 59

/FUNCT/2

#title

TrueYieldStressMPa_vs_TruePlasticStrain - 10s-1

# X Y

0.0 409.1535

0.003269060686992 420.2415

0.006930111818697 432.6

0.010444667419264 446.25

0.01364836646806 456.75

0.018589301580824 474.8667

0.021874379924321 493.12305

0.025339482510186 507.26025

0.028791504254908 519.4182

0.032231428223083 531.25485

0.035658606063999 541.36215

0.039073857673036 551.1303

0.042476834476844 559.7025

0.045868260757615 568.3293

0.049247691998806 575.97225

0.052615532789687 583.2435

0.055971597355424 589.6506

0.0593166151509 596.421

0.062650302953907 602.88165

0.065972157272864 607.8639

0.069283274188388 613.38795

0.072583138868944 618.2946

0.075872187258015 623.2779

0.079150038252912 627.45795

0.082417501766217 632.30055

0.085673728163777 635.92095

0.088919522946915 639.8469

0.092154789311739 643.7256

0.095379504511807 647.3775

0.098593691533105 650.67975

0.101797797028468 654.47025

0.10499136344905 657.60975

0.10817487992333 660.99705

0.111348320564453 664.45365

0.114511357347318 667.12695

0.117664394244064 669.74355

0.120807432277488 672.17955

0.123940737206559 674.86335

0.127064395848652 677.859

0.130178020896066 680.1795

0.133282182305355 682.93575

0.136376459004361 685.0746

0.139461485892449 687.8991

0.142536808253643 690.228

0.145602624330452 692.36895

0.148658992471595 694.3125

0.151706339300304 696.96795

0.154744128728257 698.92095

0.157772590056329 700.55475

0.1607925194482 703.65225

0.163802712305892 705.22095

0.166804116095314 707.36295

0.169796748990641 710.0205

0.172779797696021 711.0684

0.175754158491204 712.56255

0.178719690345003 714.0525

0.181676645262092 715.995

0.184624849171709 717.87135

0.187564155022526 719.15655

0.190494821916083 720.37245

0.193600270631344 720.9363

0.196220092476069 722.19105

0.199417970430916 723.4731

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

##HWCOLOR curves 3 59

/FUNCT/3

#title

TrueYieldStressMPa_vs_TruePlasticStrain - 100s-1

# X Y

0.0 428.0

0.003269060686992 440.0

0.006930111818697 453.0

0.010444667419264 467.0

0.01364836646806 478.0

0.018589301580824 497.0

0.021874379924321 516.0

0.025339482510186 531.0

0.028791504254908 544.0

0.032231428223083 556.0

0.035658606063999 567.0

0.039073857673036 577.0

0.042476834476844 586.0

0.045868260757615 595.0

0.049247691998806 603.0

0.052615532789687 611.0

0.055971597355424 617.0

0.0593166151509 624.0

0.062650302953907 631.0

0.065972157272864 636.0

0.069283274188388 642.0

0.072583138868944 647.0

0.075872187258015 652.0

0.079150038252912 657.0

0.082417501766217 662.0

0.085673728163777 666.0

0.088919522946915 670.0

0.092154789311739 674.0

0.095379504511807 678.0

0.098593691533105 681.0

0.101797797028468 685.0

0.10499136344905 688.0

0.10817487992333 692.0

0.111348320564453 696.0

0.114511357347318 698.0

0.117664394244064 701.0

0.120807432277488 704.0

0.123940737206559 706.0

0.127064395848652 710.0

0.130178020896066 712.0

0.133282182305355 715.0

0.136376459004361 717.0

0.139461485892449 720.0

0.142536808253643 723.0

0.145602624330452 725.0

0.148658992471595 727.0

0.151706339300304 730.0

0.154744128728257 732.0

0.157772590056329 733.0

0.1607925194482 737.0

0.163802712305892 738.0

0.166804116095314 741.0

0.169796748990641 743.0

0.172779797696021 744.0

0.175754158491204 746.0

0.178719690345003 748.0

0.181676645262092 750.0

0.184624849171709 752.0

0.187564155022526 753.0

0.190494821916083 754.0

0.193600270631344 755.0

0.196220092476069 756.0

0.199417970430916 757.0

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

##HWCOLOR curves 4 59

/FUNCT/4

#title

TrueYieldStressMPa_vs_TruePlasticStrain - 1000s-1

# X Y

0.0 467.0

0.003269060686992 480.0

0.006930111818697 494.0

0.010444667419264 510.0

0.01364836646806 522.0

0.018589301580824 542.0

0.021874379924321 563.0

0.025339482510186 579.0

0.028791504254908 593.0

0.032231428223083 607.0

0.035658606063999 618.0

0.039073857673036 629.0

0.042476834476844 639.0

0.045868260757615 649.0

0.049247691998806 658.0

0.052615532789687 666.0

0.055971597355424 673.0

0.0593166151509 681.0

0.062650302953907 689.0

0.065972157272864 694.0

0.069283274188388 701.0

0.072583138868944 706.0

0.075872187258015 712.0

0.079150038252912 717.0

0.082417501766217 722.0

0.085673728163777 726.0

0.088919522946915 731.0

0.092154789311739 735.0

0.095379504511807 739.0

0.098593691533105 743.0

0.101797797028468 747.0

0.10499136344905 751.0

0.10817487992333 755.0

0.111348320564453 759.0

0.114511357347318 762.0

0.117664394244064 765.0

0.120807432277488 768.0

0.123940737206559 771.0

0.127064395848652 774.0

0.130178020896066 777.0

0.133282182305355 780.0

0.136376459004361 782.0

0.139461485892449 786.0

0.142536808253643 788.0

0.145602624330452 791.0

0.148658992471595 793.0

0.151706339300304 796.0

0.154744128728257 798.0

0.157772590056329 800.0

0.1607925194482 804.0

0.163802712305892 805.0

0.166804116095314 808.0

0.169796748990641 811.0

0.172779797696021 812.0

0.175754158491204 814.0

0.178719690345003 816.0

0.181676645262092 818.0

0.184624849171709 820.0

0.187564155022526 821.0

0.190494821916083 823.0

0.193600270631344 823.0

0.196220092476069 825.0

0.199417970430916 826.0

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#ENDDATA

/END

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|Comments

- The first point of yield stress functions (plastic strain versus stress) should have a plastic strain value of zero. The yield stress functions must be strictly positive. The yield stress should be either constant or increasing (no softening to avoid numerical instabilities).

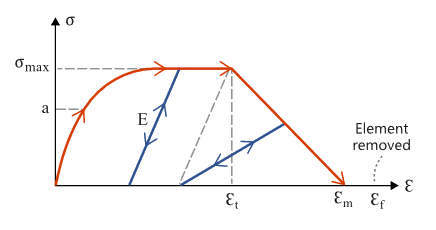

- Element deletion:

- Once (plastic strain) reaches , in one integration point, the element is deleted.

- If

(largest principal strain) reaches

, the yield stress is reduced using the following

relation:

- If reaches ( ), the stress in element is reduced to 0 (but the element is not deleted).

- Once reaches (maximum tensile failure strain), the element is deleted.

- Once the damaged yield stress value

, interpolated or extrapolated reaches 0, the element is

deleted.

Figure 1.

- The kinematic hardening model is not available in global formulation (N=0 in shell property keyword) that is, hardening is fully isotropic.

- In case of kinematic hardening and strain rate dependency, the yield stress depends on the strain rate.

- Strain rate filtering is used to smooth strain rates.

- The first function in fct_ID1 is used for strain rate values from 0 to its corresponding strain rate, strain rate 1.

However, the last function used in the model does not extend to the maximum strain rate;

for higher strain rates, a linear extrapolation will be applied. This could lead to

instability and/or unusual deformation. This instability can be overcome by repeating the

stress strain curve, corresponding to the last strain rate, again with a much higher

strain rate.

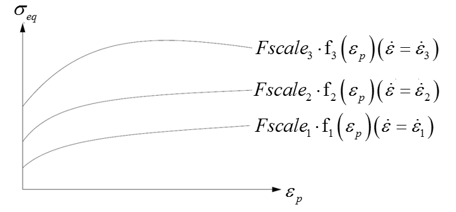

Figure 2.

- fct_IDp is used to distinguish the behavior in tension and compression for certain materials (pressure dependent yield). This is available for both shell and solid elements. The effective yield stress is then obtained by multiplying the nominal yield stress by the yield factor corresponding to the actual pressure.

- If , the yield stress is interpolated between and .

- If , function is used.

- Beyond the last point of the

plastic strain versus stress input curves, the yield stress is extrapolated.

Figure 3.

Where,- Total strain rate for VP =0

- Plastic strain rate for VP =1

- If the last point of the first (static) function equals 0 in stress, default value of is set to the corresponding value of .

- Strain rate values must be given in strictly ascending order.

- The evolution of Young's

modulus:

- If fct_IDE > 0, the curve defines a scale factor for Young's modulus

evolution with equivalent plastic strain, which means the Young's modulus is scaled by

the function

:

The initial value of the scale factor should be equal to 1 and it decreases.

- If fct_IDE = 0, the Young's modulus is calculated as:Where, and are respectively the initial and asymptotic value of Young's modulus, and is the accumulated equivalent plastic strain.Note: If fct_IDE = 0 and = 0, Young's modulus remains constant.

- If fct_IDE > 0, the curve defines a scale factor for Young's modulus

evolution with equivalent plastic strain, which means the Young's modulus is scaled by

the function

:

- When you specify

or

and

, a damage output variable is available using

/ANIM/ELEM/DAMG or /H3D/ELEM/DAMG. This damage

variable is computed as:

- When is specified and the /NONLOCAL/MAT option is activated, non-local plastic strain is used to compute the damage variable.

- When VP = 0 and Fcut is set to the default value, it is automatically updated according to the unit system used for the computation.

- When VP = 1, the strain rate dependency is computed considering the plastic strain rate. This approach is more consistent with physics and is closer to a full visco-plastic approach. In that case, the plastic strain rate is always smoothed with a cut-off frequency of 10000Hz that cannot be changed by users.

- By default, the hydrostatic pressure is linearly proportional to the density:

Where,

is the bulk modulus and

.

An additional Equation of State (/EOS) card can refer to this material in order to define a nonlinear dependency between hydrostatic pressure and volumetric strain. This behavior is only available for solid and SPH elements.